Phoenix Sintered Metals utilizes several sintering process to produce our customers' products to their specifications.

Phoenix Sintered Metals utilizes several sintering process to produce our customers' products to their specifications.

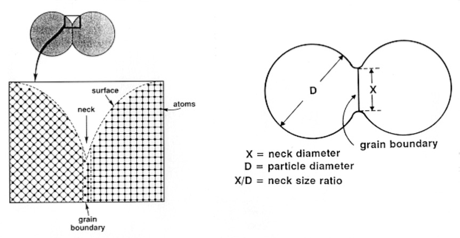

Sintering is an atomic diffusion process in which metallurgical alloying and bonding takes place and material properties established.

Although the majority of sintering in the industry is done on conventional continuous mesh belt furnaces at approx. 1120C/2050F, Phoenix Sintered Metals has the expanded capability for both Sinter hardening and High temperature Sintering.

Although the majority of sintering in the industry is done on conventional continuous mesh belt furnaces at approx. 1120C/2050F, Phoenix Sintered Metals has the expanded capability for both Sinter hardening and High temperature Sintering.

Sinter hardening is the use of a specific alloy along with an accelerated cooling system that will form a significant amount of martensite in the component. Benefits are the elimination for secondary quench and tempering while reducing distortion, resulting in overall improved dimensional control.

Sinter hardening is the use of a specific alloy along with an accelerated cooling system that will form a significant amount of martensite in the component. Benefits are the elimination for secondary quench and tempering while reducing distortion, resulting in overall improved dimensional control.

High temperature sintering increases temperature to 1285C/2350F and higher for the sintering of Stainless-Steel grades and improvement of mechanical properties for Ferrous base materials.