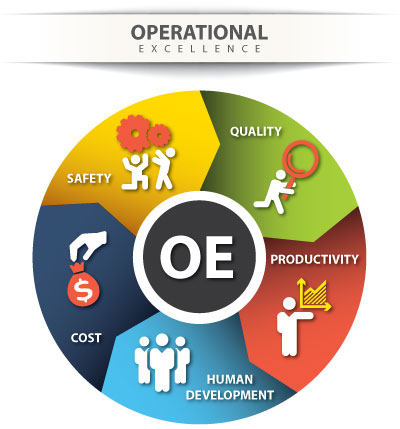

Phoenix Sintered Metals started its journey of Operational Excellence in 2011. Operational Excellence is a philosophy and a system for continuous improvement in an organization that addresses ideals and culture. It takes Lean Manufacturing a step further. It is a strategy for how to conduct business, using a system of tools and techniques within specific method. The focus is on what the customer needs, with employees empowered to increase value and eliminate waste. Operational Excellence is a balance of employee development and Operations, driving ideas and solutions. It focuses on fact management and two-way cascading communication channels enabling the organization and leadership to focus on best practices, top level concerns and long-term goals.

Phoenix Sintered Metals started its journey of Operational Excellence in 2011. Operational Excellence is a philosophy and a system for continuous improvement in an organization that addresses ideals and culture. It takes Lean Manufacturing a step further. It is a strategy for how to conduct business, using a system of tools and techniques within specific method. The focus is on what the customer needs, with employees empowered to increase value and eliminate waste. Operational Excellence is a balance of employee development and Operations, driving ideas and solutions. It focuses on fact management and two-way cascading communication channels enabling the organization and leadership to focus on best practices, top level concerns and long-term goals.

Phoenix has an Operational Excellence solution system that trains, encourages, and empowers employees to conceive and implement improvements in their daily work. With open communication at all levels, this creates a culture of thinkers and problem solvers. Employees are both rewarded and recognized for their solutions.

Brief cascading meetings are held every day, at every level of the organization to ensure key focus areas are being addressed, and that the entire team is in alignment with strategy, top level concerns, short and long-term goals.

Success in implementing and sustaining Operational Excellence for the long term depends on our PEOPLE (leadership, team culture and values). It is in our DNA and at the core of everything we do.

Success in implementing and sustaining Operational Excellence for the long term depends on our PEOPLE (leadership, team culture and values). It is in our DNA and at the core of everything we do.

- Safety

- Quality

- Productivity

- Human Development

- Cost