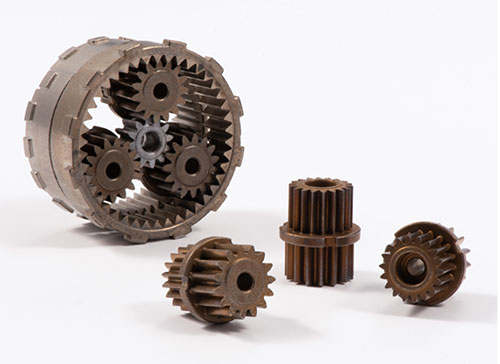

From Powder to Parts, we collaborate with our customers to determine the right material, part design, tooling, and process to optimize performance and value.

We see the material and process as a system to maximize the mechanical properties and cost efficiencies. We have a wide range of material solutions and complimentary processes to support your product requirements. We also have the engineering depth and knowledge to develop custom material solutions if the application and part environment would demand.

Our experienced engineering staff can then implement full 3-D Computer-Aided-Design software for part, process, and design. The engineering team also uses CAD/CAM software to design and model powder metal parts for tooling and equipment to ensure a robust design and process.

From the highly engineered complex geometry to product with less complexity, we can provide a value solution.

We look forward to working together, sharing our successful examples of our system engineering and award-winning parts and develop your solution.

Work with our team to transform your concepts to reality.

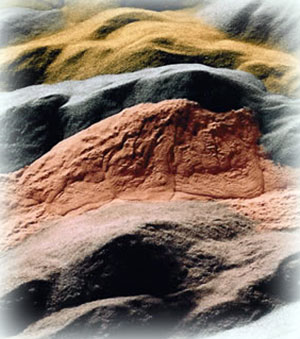

Powder Metal Materials Include:

- Iron & Carbon Steel

- Copper Infiltration

- Sinter Hardened Steel

- Low Alloy Steel

- Iron-Phosphorous

- Copper Steel

- Nickel Steel

- Iron-Nickel

- High Alloy Steel

- 300 Stainless

- 400 Stainless